Concrete Lifting

WHY USE HIGH-DENSITY POLYURETHANE FOAM

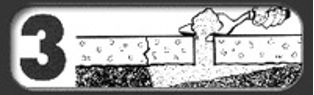

In Colorado, the most common reason for sunken concrete is inadequate or incorrect drainage, where a void occurs under your concrete due to water runoff. Many companies offer lifting services that utilize a topsoil and concrete slurry, usually referred to mudjacking or slabjacking. Unlike leveling done with polyurethane foam, the material used in the mudjacking process will continue to wash away, and the sinking issues you’re currently experience will reappear.

Rapid Concrete Lifting uses high-density polyurethane foam to raise and level your sunken concrete. We are confident that high-density polyurethane concrete leveling is the most efficient and cost effective way to raise and stabilize existing concrete slabs.

In addition, polyurethane offers many advantages compared to other concrete leveling or replacement methods:

More Economical

Provides a permanent solution that’s 50-75% cheaper than the cost of removing and replacing existing concrete.

More Efficient

Over 80% faster than alternative methods of repair. Material hardens in minutes allowing the project to be completed in hours versus the days or weeks that other methods require.

Better Structural Integrity

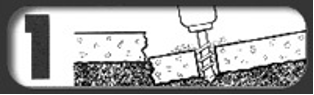

To help maintain structural integrity of the concrete pavement injection holes are only 5/8″ in diameter (a dime-sized hole), versus 3″ or larger for other concrete lifting methods. Polyurethane foam does not stress the concrete, due to even coverage & low viscosity of the urethane, and offers up to 250 psi compressive & tensile strength.

Lighter Weight

Polyurethane only adds 2.5-5 pounds per cubic foot to the sub base, compared to the 100 pounds plus that mud-jacking grout adds. This means that polyurethane foam is the ideal method for lifting areas where additional weight is a concern, such as basements and/or concrete areas over basements or crawl spaces.

Superior Accuracy

Polyurethane foam to creates its own hydraulic lift so we can control the lifting process precisely to within 1/10th of an inch. Other methods must account for shrinkage of material by over-lifting the area, whereas polyurethane will never shrink. Also, unlike traditional “mud jacking” methods that utilize concrete grout (which may continue to wash away if water drainage is what’s causing the your concrete to sink), polyurethane foam is hydrophobic and thus will not wash away.

Less Disruption

Due to the fast curing time of high-density polyurethane, traffic control can be removed and lanes reopened to traffic immediately after the injection process. Nighttime scheduling lessens delays and inconveniences.

Higher Durability

Polyurethane’s compression strength provides a solid and dense product, while at the same time, its tensile strength and elongation allows for the material to be pliable. This allows it to permanently support the structure by being tough yet forgiving.

Conformability

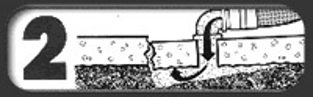

By expanding up to 30 times its liquid volume, polyurethane foam material moves laterally beneath the pavement filling all voids. Additionally it perfectly contours to the size and shape of the voids to fully completely support the pavement with 100% coverage.

Compaction Ability

An additional benefit during the lifting process is the compaction of base soils through the resistance of lifting the concrete structure. The material bleeds into the sub base and binds soil particles together strengthening the base material.

Moisture Resistant

Our specially formulated polyurethane material is designed for wet conditions. It’s hydrophobic properties displace and repel water without being compromised and replaces any missing sub base with a solid/dense material unaffected by moisture.

Moisture Seal Barrier

Polyurethane seals the underside of concrete pavement joints and cracks to eliminate water penetration and erosion issues. It sub-seals floors and waterproofs walls.

Infrastructure Rehabilitation

Puts counties, cities and municipalities in control of their aging infrastructure by saving them time and money. Polyurethane foam lifting has been used by DOTs for over 30 years on highways and bridge approaches.

Ready to get your old concrete looking like new again? Schedule your free estimate today, or call

970-616-0730.